Discover the 4.0 process for the preparation, mixing and dispatch of dyestuffs for textile dyeing plants

A new concept of color kitchen 4.0 capable of managing the different dyestuff mixtures to be sent to the corresponding dyeing machine in a fast and safe way. Reliability to …

A new concept of color kitchen 4.0 capable of managing the different dyestuff mixtures to be sent to the corresponding dyeing machine in a fast and safe way. Reliability to grammage of the recipe with a high impact on raw material savings.

The color kitchen of a textile industry is one of the most precise processes. This is the point where the receipe developed in the laboratory is used for a large-scale production. The entire dyeing process depends on the success on the correct planning. The advances in industry 4.0 have allowed us to modernize this procees through automation, where nothing is left to chance.

All movements are now recorded and traceable. From the management of the dyestuffs to the controlled dissolution adapted to each type of product and the corresponding delivery to the dyeing machines to initiate the production process.

Intelligent organization, flawless production

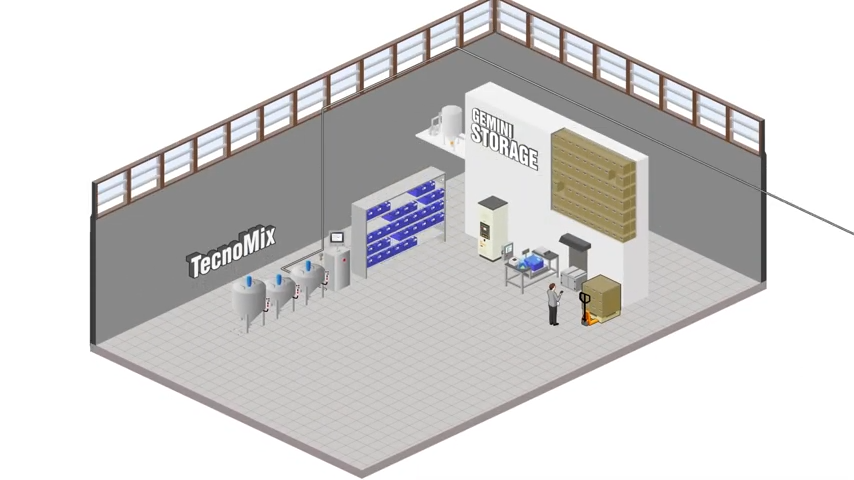

The dyeing plant process begins with the reception, classification, and storage of powder dyes. Through a barcode scanner, these raw materials are organized by batch and color family, which is recorded in the system and allowing a real-time inventory to be kept.

These products are stored in a smart storage system to control the incoming and outcoming products allowing a real stock control.

To prepare a production order, we only need to scan the recipe barcode in our MES dyeing software, such as InfoTint. This system will allow us to locate and select the dyes to be used in the recipe. In addition, the software will indicate the exact quantity to be used according to the specific of recipe and process.

Connected to a weighing module such as TexPes, we will be able to weigh the amount of colorant to be used in the solution, which will be registered in the dosing system, and certify the amount of powder colorant used by discounting it from the stock in the warehouse.

There are several methods to prepare the dyestuffs to be used during a production shift. The most ecological, efficient, and recommended is to use a water-soluble bag.

Therefore, a box is prepared with the water-soluble bag extended and placed on the scale. Then the weight of these accessories is tared to introduce the grammage indicated on the screen.

Once the preparation will be ready to be stored until its use, it is identified by a bar code. This optimizes the weighing process, avoiding wastage of raw materials and contributes to the correct cleanliness of the sector. It is an infallible system to plan the entire raw material preparations and having them under strict control.

Color dosing system

TecnoMix is the dosing machine and color kitchen where powder solutions are safely prepared.

It has a pump module connecting to the conical preparation tanks, built in stainless steel for longer life. The interior of TecnoMix is finished in mirror effect, with practically no elements, designed to obtain the best possible mixture.

This system also allows us to perform an automatic and efficient washing of the machine, making it available for the next mixing in a matter of minutes.

TecnoMix achieves the perfect dissolution and mixing based on the recipe, and the preset parameters such as mixing time, water temperature or agitation method. By scanning the barcode of the recipe directly into the machine, with no need to enter manual parameters.

An alarm system alerts us when to introduce the colorant just scanning the barcode of the powder previously prepared. The security system will open the safety lid to introduce the water-soluble bag and the mix process according to the parameters in the recipe will begin.

When the mixture is finished, TecnoMix will deliver it to the corresponding dyeing machine to start the process.

TecnoMix offers the following advantages:

- Optimal and precise dissolution of the dye considering the parameters of time, temperature, and agitation method.

- A modular and expandable system able to grow according to the production capacity.

- Lid opening by sophisticated safety system.

- Configurability and great adaptability to the different technical requirements of the recipe and dye family.

- Traceability and transparency of the process.

- Latest generation technology thanks to the Atlantis PCT-900 controller.

- Full connectivity to InfoTint, and other MES software in the market.

From EAS we want to contribute to the textile industry, by adapting the machinery to technology and industry 4.0. A great investment to optimize resources, minimize the environmental footprint without compromising the quality of the textile product.

If you want more information, tell us about your project, we will be happy to advise you without obligation. We also invite you to follow us on our Linkedin page.