Challenges and opportunities in the textile industry

The textile industry faces several challenges and exciting opportunities in today’s times. One of the most significant challenges is the growing global competition, with an increasing number of countries entering …

The textile industry faces several challenges and exciting opportunities in today’s times. One of the most significant challenges is the growing global competition, with an increasing number of countries entering this sector. This means that companies need to become better and more efficient to remain competitive. Additionally, there is a growing pressure to be more environmentally friendly and conduct business responsibly.

Challenges in textile industry

But it’s not all challenges; there are also exciting opportunities in the textile industry. Technology has advanced significantly, allowing us to manufacture higher-quality clothing more quickly. Furthermore, online commerce has opened up new avenues for selling clothing and reaching a wider audience. Here are some of the most common challenges faced by the industry:

Production chain issues: the textile production chain involves a series of steps from sourcing raw materials to delivering the final product. One of the significant challenges is that these steps are often not well-coordinated or communicated. This can lead to issues such as production delays, additional costs, and missed opportunities. To address this challenge, it is essential for all departments to work together, ensuring proper coordination for smooth and efficient production.

Resource management: textile manufacturing requires the use of various resources, such as energy, water, dyes, and other materials. If these resources are not managed properly, it can result in increased costs and a negative impact on the environment. Additionally, inefficient energy use can raise production costs and contribute to greater natural resource consumption. Precise management of these resources is crucial to control costs and ensure sustainable and environmentally friendly production.

Disconnected systems: it is crucial for all systems and processes to be interconnected and communicate effectively for efficient operations. If systems are not connected, there can be communication and coordination problems that negatively affect efficiency. For example, if the inventory management system is not linked to the production system, there may be difficulties in keeping inventory updated, leading to product delivery delays or excessive material purchases. Implementing integrated management systems is essential to address this challenge.

How can we Solve these issues with technology?

Today, technology can be used to address these challenges in the textile industry effectively. An highly effective solution is to use a system called ERP (Enterprise Resource Planning) specifically designed for the textile industry. Here’s how it can help:

Improved production chain: an ERP provides a comprehensive, real-time view of all operations in the textile factory, from raw material acquisition to final product delivery. This is beneficial in several ways:

– Effective coordination among departments.

– Reduction of delays through early problem detection.

– Optimization of human resources allocation for maintaining a consistent workflow.

Accurate resource tracking: An ERP also enables meticulous tracking of resources used in textile product manufacturing. This is crucial for:

– Precisely recording material and energy consumption at each production stage.

– Identifying consumption patterns to adjust production accordingly.

– Reducing operational costs through informed decision-making.

Real-Time data: the ability to access up-to-date information in real time is fundamental for effective management:

– Informed decision-making based on real-time data on orders, inventory, and production.

– Greater agility and responsiveness to market demands.

– Improved product quality by identifying and addressing issues promptly.

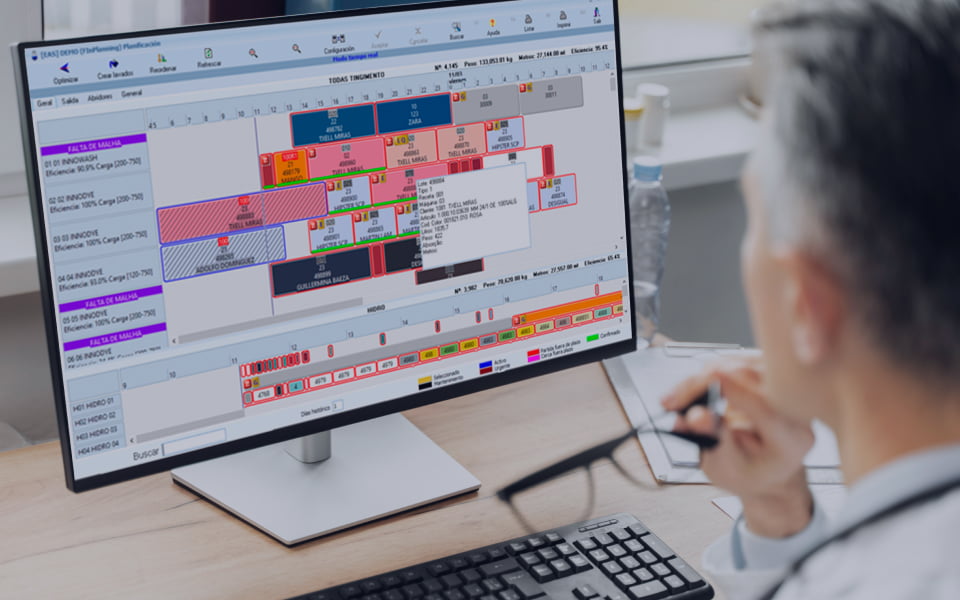

Leading the digital transformation with TexDrive

In the competitive world of the textile industry, having an effective solution can make all the difference. That’s why TexDrive stands out as the ideal choice to take your textile factory to the next level, thanks to:

Outstanding customization: We understand that each textile factory is unique. TexDrive precisely adapts to your specific needs, making it easy to implement and use from day one.

Comprehensive integration: TexDrive covers all critical aspects of your business, from sales to finances, providing you with a complete and synchronized view of your company.

Remote access for the modern era: Flexibility is essential in today’s world. TexDrive allows you to manage your textile factory from anywhere and at any time, giving you full control and the ability to make informed decisions in a constantly changing market.

Don’t let the challenges of the textile industry hold you back. Discover how TexDrive can help you achieve success in the textile industry by improving efficiency, reducing costs, and enhancing the quality of your textile products.