Top 3 software applications most commonly used in textile industry

4.0 textile industry (cyber industry of the future or smart industry) corresponds to a new way of organizing production resources by continuously automating industrial practices and processes through technology. The …

4.0 textile industry (cyber industry of the future or smart industry) corresponds to a new way of organizing production resources by continuously automating industrial practices and processes through technology.

The aim is to improve communication, self-control, and to manufacture smart machines to diagnose and analyze common issues without human intervention.

One of the keys is the management of accurate data. This helps us to make decisions when implementing process improvements to increase performance and reduce production costs.

This only can be achieved with a good computer software adapted to the activity of company. In the case of the textile sector, we have 3 different types of specific software.

A technological boost to make textile companies grow by focusing on the quality of the final product and customer satisfaction.

What types of software are used in the textile industry?

This question covers a range full of possibilities. The most accurate answer would be: “depending on the company and the economic sector to which the activity belongs”.

In the textile industry there is also a great diversity of computer programs used since many departments are involved. Software such as design, tailoring and pattern making, administration, among many others. These programs are dedicated specifically to carry out specific tasks.

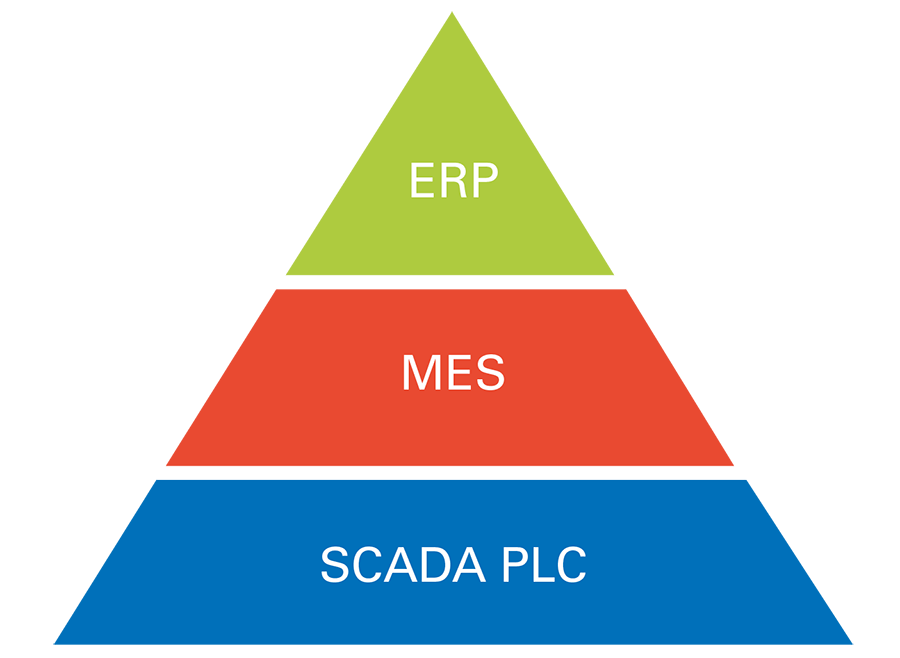

Focusing on the manufacture of fabrics as raw materials, we find 3 types of software forming the fundamental pillar. Each of them fulfills a specific function and can be combined at the same time understanding the system as a pyramid divided into 3 levels.

At the base of the pyramid, we will find the SCADA and PLC software, used in the automation of production machines, process control and data collection.

At the middle point we will find the MES software in charge of the management of all these data, the production planning, and the execution of the work orders.

The top of the pyramid is we find the ERP system, in charge of centralizing all the company’s work systems, as well as helping in the global vision of the company and in business decision making.

Let’s analyze them in detail from smallest to largest.

SCADA and PLC software

This type of management software constitutes the body and the brain of the production machines.

The SCADA (Supervisory Control And Data Acquisition) system is a software application specially designed for use in computers for manufacturing control, providing communication with field devices (autonomous controllers, programmable logic controllers, etc.) and controlling the process automatically from the computer screen.

In addition, this type of management software provides all the information generated in the production process to various users, both at the same level and from other supervisors within the company: quality control, supervision, maintenance, etc.

A SCADA system usually consists of the following sub-systems:

- A human-machine interface (HMI) is the device that presents process data to a human. Through this interface the person can observe and control the process (monitoring). Signals are routed to the HMI through devices such as input/output cards in the computer or programmable logic controllers, also known as PLC (Programmable Logic Controller).

- A computer supervisory system, which acquires data from the process in a pre-programmed processing and sends commands (control) to the process.

MES Software

The MES system (Manufacturing Execution System) is responsible for the control and planning of all production processes. This software focuses on the control and analysis of the data obtained by SCADA and PLC systems, to obtain the best results in the manufacture of the final product, such as optimizing the cost of production.

ERP Software

The ERP (Enterprise Resource Planning) is a software that will provide an overview of the business by unifying all departments in a single point. Its global vision helps in the overall planning of all areas of the company, from human resources, accounting, marketing and communication, sales, production, among others.

Each department can have its own specific management software, so the ERP would be like the meeting point where to control the entire company to help in making business decisions.

Having an adapted textile management software is the core of 4.0 industry. If you want to take a step towards automation and integration of all textile management and production processes, contact us! It will be a pleasure to help you.